Blog

How to Choose the Right Manitou Telehandler for Confined or Uneven Terrain

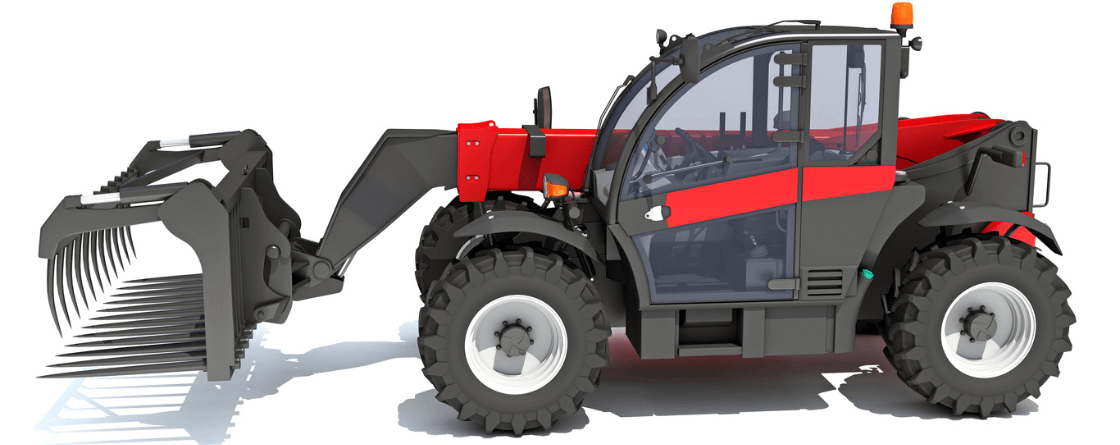

Job sites present a clear reality: ground conditions vary, and space is often limited. You have faced muddy patches, tight squeezes, and equipment that falls short. Selecting the right telehandler requires practical adaptability. When confined spaces or unpredictable terrain define your workday, a standard lift fails. A Manitou telehandler earns its reputation in these conditions.

Why Confined Spaces and Uneven Terrain Require Specialised Telehandlers?

Every job site presents unique challenges. Confined spaces, intricate internal warehousing, or tight agricultural buildings, demand machines with pinpoint manoeuvrability and a footprint that prevents bottlenecks. These environments push operators and demand stability, robust traction, and exceptional ground clearance. Forcing a standard forklift or loader into these situations risks decreased productivity, invites safety hazards, and damages equipment.

A purpose-built telehandler excels in these conditions. Known for its ability to lift, move, and place materials in hard-to-reach places, this equipment combines power, finesse, and versatility for complex sites.

Key Considerations When Selecting Your Manitou Telehandler: An Expert’s View

Choosing the ideal Manitou telehandler demands a strategic assessment based on practical experience.

1. How Do I Assess My Site’s Dimensions and Ground Conditions for a Telehandler?

Before considering models, understand your ground conditions and available space.

- Confined Spaces: You know the routine: tight doorways, congested aisles, unexpected overhead obstructions. For restricted areas, compact models with superior turning radii are essential. Look for machines offering multiple steering modes, such as two-wheel for road travel, four-wheel for general site work, and crab steer for unparalleled lateral movement in tight spots. This agility keeps your project flowing, not stuck.

- Uneven Terrain: This is where the machine’s foundation proves its strength. Rough terrain demands robust machines with excellent ground clearance, a strong, stable chassis, and four-wheel drive. Tire selection proves crucial. Pneumatic tires with deep, aggressive treads deliver necessary grip on soft or slippery surfaces.

2. What Lift Capacity and Reach Do I Need for My Telehandler Project?

A telehandler delivers impressive lift capacity and reach. Understanding your project’s precise demands remains paramount. This is no place for estimation; accurate measurement is key.

- Load Weight: What is the heaviest load you will lift? Always ensure the machine’s rated capacity safely exceeds your heaviest loads. Overloading poses a critical safety hazard and leads to costly downtime, structural damage, and potential regulatory issues.

- Lift Height: How high do you need to place materials? Consider the maximum extension of the telescopic boom, including its stability at full extension.

- Forward Reach: How far forward do you need to extend the load, especially over obstacles, across trenches, or into a building? The precision of the boom matters here.

These models offer a range of boom lengths, heights, and lift capacities. Match these precisely to your project’s specific requirements, ensuring you have the right tool.

3. Which Telehandler Attachments Are Best for Confined or Uneven Terrain?

A telehandler unlocks its potential through proper outfitting. Its versatility improves with a wide range of interchangeable attachments, transforming your single machine into a multi-tasking powerhouse:

- Forks: Standard for palletised loads.

- Buckets: Essential for moving loose materials like gravel, sand, or spoil.

- Work Platforms/Baskets: For safe and stable access at height, especially where traditional scaffolding is impractical or too time-consuming.

- Winches/Jib Booms: These extend reach and provide crucial lifting points for awkward, non-palletised loads that would otherwise require a crane.

- Specialised Tools: From tire clamps to sweepers, this equipment adapts with a variety of tools for specialised industrial tasks.

This adaptability saves time on site and reduces the need to invest in or hire multiple specialised machines, cutting down on operational costs and simplifying logistics.

4. Diesel, Electric, or LPG: Which Manitou Telehandler Power Source is Right for My Site?

Telehandler models come with various power sources. Choosing the right one considers fuel cost, environmental suitability, and operational efficiency:

- Diesel: This remains the top choice for raw power and endurance, ideal for demanding outdoor applications on rough terrain. If you work in partially enclosed spaces, proper ventilation is a critical safety requirement to manage emissions.

- Electric: This is the preferred choice for indoor use or confined spaces where emissions, noise, and air quality are paramount. Electric models offer quiet, emission-free operation, making them perfect for sensitive environments like warehouses, food processing plants, or enclosed construction sites.

- LPG: A versatile option, LPG offers a good balance of power and cleaner emissions than diesel, making it suitable for both indoor and outdoor use where some emissions control is necessary without sacrificing power.

Glosrose offers comprehensive forklift hire options, including diesel, electric, and LPG, ensuring you select the optimal power source for your specific site conditions.

5. What Essential Safety Features Should I Look for in a Telehandler?

In this business, safety forms the bedrock of every successful operation. Modern telehandler models pack advanced safety features designed to protect your team and your investment. Always look for:

- Advanced Stability Control Systems: These are crucial on uneven ground. They monitor machine stability, providing warnings or interventions to prevent rollovers.

- Load Management Systems: These are essential. They prevent dangerous overloading and ensure the machine operates within its safe working parameters, especially at extended reaches.

- Visibility: Good cabin design, strategically placed mirrors, and optional camera systems (front, rear, and boom-mounted) improve operator awareness, particularly when manoeuvring in confined spaces or around busy sites.

- Ergonomics: A comfortable and intuitive operator station directly reduces operator fatigue and improves precision. This is vital during long shifts and complex manoeuvres. These machines feature modular dashboards, accessible cabs, and excellent manoeuvrability, all contributing to a safer, more productive operator experience.

The Glosrose Advantage: Expertise-Driven Equipment Matching – Your Project, Our Priority

Choosing the right Manitou telehandler for confined or uneven terrain can be complex. Glosrose’s decades of expertise come to the forefront here. We deliver tailored solutions, forged from real-world understanding.

Our seasoned team works directly with you, delving into your exact requirements and drawing on over 45 years of hands-on experience. We recommend the perfect Manitou telehandler from our extensive, wide fleet. You can choose short-term rental from one week for a quick project or long-term contract hire for sustained operations. We ensure you receive a reliable, ready-to-go Manitou telehandler that fits your project, your budget, and gives you peace of mind.

Glosrose also provides comprehensive fleet management. This includes routine maintenance, ensuring full LOLER/PUWER compliance (which, as you know, is essential), and a robust 24-hour parts delivery service. Our rapid nationwide response and impressive first-time fix rates mean you can trust your equipment will always perform when you need it most, minimising costly interruptions.

Elevate Your Project with Glosrose

Do not let challenging terrain or confined spaces dictate your project’s pace. Partner with Glosrose to secure the ideal Manitou telehandler that brings precision, power, and, most importantly, practical safety to your worksite.

Speak to our expert team for advice and a tailored quote!

Glosrose commits to ensuring you have the reliable, ready-to-go kit you need, when you need it.

You May Also Like

How Doosan Fork Lifts Solve the Dock-to-Stock Bottleneck for High-Velocity Warehouses

Why Agility Overtakes Reach in Modern Urban Telehandler Selection

Get in Touch

Not sure what you are looking for or need some advice for your requirements? Get in touch with us today and a member of our experienced team will be more than happy to help answer your questions.