Blog

Strategic Scissor Lift Selection: A Data-Driven Guide

The selection of scissor lifts is a critical operational decision with direct implications for project efficiency, safety compliance, and financial outcomes. A mismatch between equipment and the operational environment can result in costly delays and heightened risk. This guide provides a strategic framework for making an informed choice, moving beyond surface-level specifications to a data-driven analysis of your project’s precise requirements.

Operational Profiles: Matching Power Source to Environment

The most fundamental decision in scissor lift selection is the power source, which must be aligned with the operational profile of the work site.

- Electric Scissor Lifts: These units are engineered for controlled, indoor environments. Their zero-emission, low-noise operation is essential for spaces with air quality or sound restrictions, such as warehouses, retail spaces, and food processing plants.

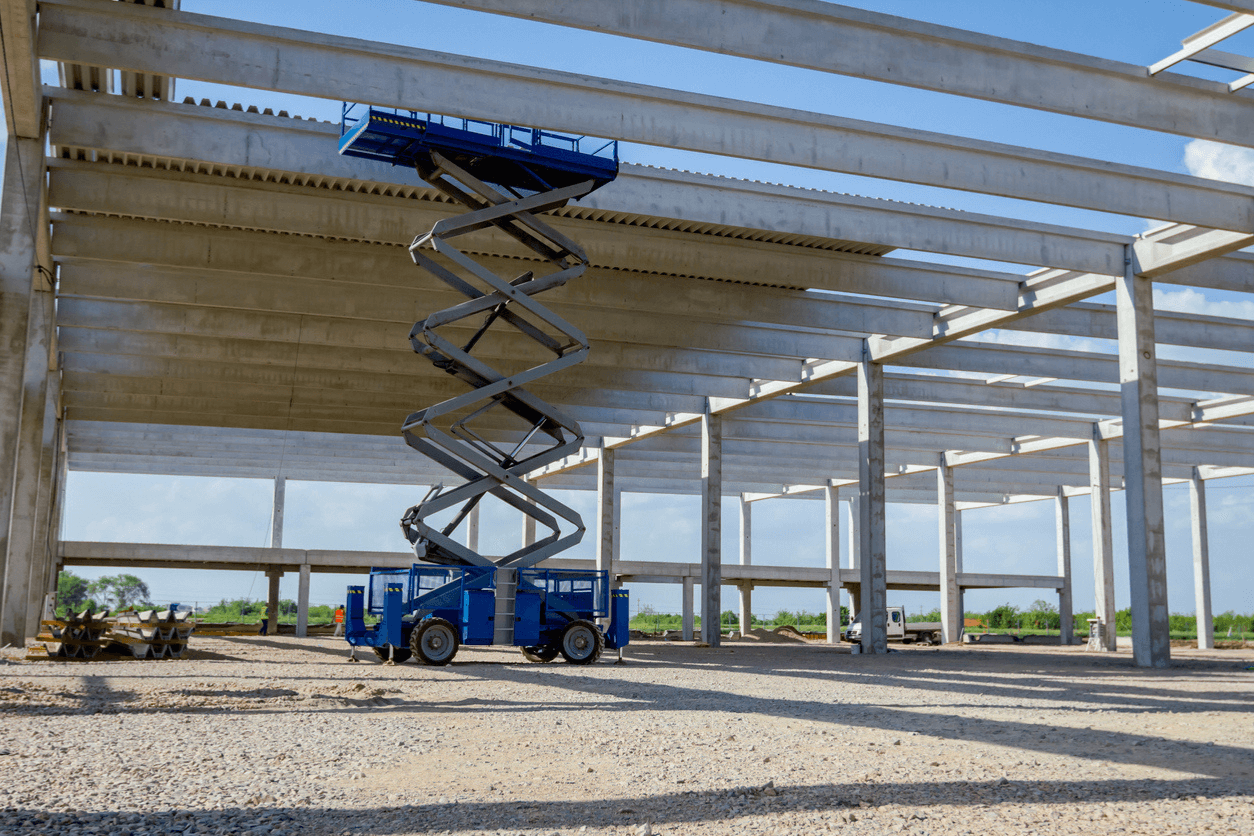

- Diesel Scissor Lifts: These are high-performance units built for durability and rugged conditions. Their robust design, powerful engines, and rough-terrain tires make them the definitive choice for unpaved outdoor sites, including construction zones, fields, and large-scale industrial yards. They offer superior lift capacity and are designed to navigate challenging ground conditions.

Key Metrics for Performance Optimisation

A strategic choice relies on a precise analysis of key project metrics, ensuring that the selected equipment is optimised for performance and safety.

- Working Height: This metric is the maximum height an operator can safely reach. It must be calculated by factoring in the platform height, operator reach, and any overhead obstructions on the work site. Overlooking this detail is a common cause of operational inefficiency.

- Platform Capacity: This is the maximum permissible load for the platform, which includes the weight of all personnel, tools, and materials. A thorough calculation of the total load is required, as exceeding this capacity is a primary safety and compliance violation.

- Access & Dimensions: A detailed assessment of all access points including doorways, gates, and internal aisles is essential. The dimensions of the lift must be compatible with the work environment to ensure full site accessibility and prevent property damage.

Mitigation of Common Operational Risks

Proactive risk mitigation is a hallmark of strategic planning. These are three common missteps that can be avoided through a structured approach.

- Inadequate Ground Assessment: The ground’s stability and grade must be evaluated. Even lifts designed for rough terrain can become unstable on steep slopes or in soft, uncompacted soil, leading to a critical safety failure.

- Improper Height Calculation: A common mistake is to only measure the highest work point. Obstacles such as ceiling joists or ducting must be included in the calculation to ensure an adequate safety margin.

- Oversizing the Equipment: For indoor applications, selecting a lift with an unnecessarily wide turning radius can severely limit manoeuvrability in tight aisles and corners, impacting workflow and increasing the risk of collateral damage.

Advanced Features and Attachments for Enhanced Performance

To optimise scissor lifts for specific tasks, a strategic investment in advanced features and versatile attachments is essential. These are not merely add-ons but tools for increasing productivity, improving safety, and reducing the need for multiple pieces of equipment.

- Power to Platform: Many modern lifts come with power outlets or air lines directly on the platform. This feature is a significant advantage, as it allows operators to use corded power tools or air-powered equipment without the safety hazards and logistical complications of running long extension cords up the lift. This reduces trip hazards and streamlines workflow, saving valuable time.

- Auto-Leveling Outriggers: For outdoor and rough-terrain lifts, auto-leveling outriggers are a game-changer. They automatically detect and compensate for uneven ground, ensuring the lift remains perfectly stable and level. This technology not only enhances safety by preventing rollovers but also expands the range of environments where the lift can be safely and compliantly used.

- Attachments and Work Trays: The versatility of a scissor lift can be significantly increased with simple attachments. Features like pipe racks, material trays, or specialised work platforms allow operators to transport and manage all necessary tools and materials in a single trip. This reduces the time spent ascending and descending, significantly boosting on-platform productivity and efficiency.

- Telematics and Fleet Management: For businesses managing multiple lifts, telematics provides a data-driven approach to fleet management. These systems track the machine’s usage hours, location, and maintenance needs in real-time. This data allows you to optimise equipment allocation, schedule proactive maintenance to prevent failures, and ensure full compliance with operational regulations.

Regulatory Compliance and Operator Qualification

Adherence to regulatory standards is a non-negotiable component of any lifting operation. Compliance protects personnel, equipment, and the business from legal and financial repercussions.

- LOLER & PUWER: In the UK, the Lifting Operations and Lifting Equipment Regulations (LOLER) require regular statutory inspections by a competent party. The Provision and Use of Work Equipment Regulations (PUWER) mandate that all equipment be safe and suitable for its intended purpose.

- IPAF Certification: Operator competence is a legal and ethical requirement. IPAF training is the industry-standard certification for Mobile Elevating Work Platforms (MEWPs), providing operators with the skills to ensure safe and compliant use.

Glosrose: A Commitment to Data-Driven Solutions

At Glosrose, our expertise is applied to deliver data-driven solutions, not just equipment. We work with you to analyse your project’s operational data and physical constraints, recommending a scissor lift that maximises ROI while ensuring absolute safety. Our fleet is rigorously maintained and fully compliant with all regulatory standards.

Our service model is structured to meet your business needs with precision, offering flexible hire options, strategic fleet management, and a commitment to uptime. We provide the tools, and the insights required to make a confident, well-justified choice for your operation.

Visit our hire page to explore our complete fleet and hire options.

Make a Strategic Investment with Gloserose

The decision to hire a scissor lift is a strategic investment in your project’s success. By moving beyond a simple visual assessment and employing a data-driven approach, you can select the optimal equipment that aligns with your operational profile and compliance requirements.

Contact us today for a strategic guidance and reliable equipment you need to ensure your project’s success.

You May Also Like

How Doosan Fork Lifts Solve the Dock-to-Stock Bottleneck for High-Velocity Warehouses

Why Agility Overtakes Reach in Modern Urban Telehandler Selection

Get in Touch

Not sure what you are looking for or need some advice for your requirements? Get in touch with us today and a member of our experienced team will be more than happy to help answer your questions.