Blog

Telehandler Operator Errors That Cost Projects Time and Money

In this business, I’ve seen a lot of things go wrong, but a telehandler operator’s mistake is often the most expensive. It starts with a simple mistake such as a lifted boom extended just a foot too far, or a tire a few pounds under pressure. You don’t see the problem until the machine lurches and a day’s work grinds to a halt. This guide is a playbook for avoiding those exact moments and building a culture of on-site safety.

Your First Move: The Unavoidable Pre-Shift Check

“The machine was working perfectly fine yesterday, so it will be fine today. The operator can just hop in and start the work without a second thought.” You have likely heard people say this often.

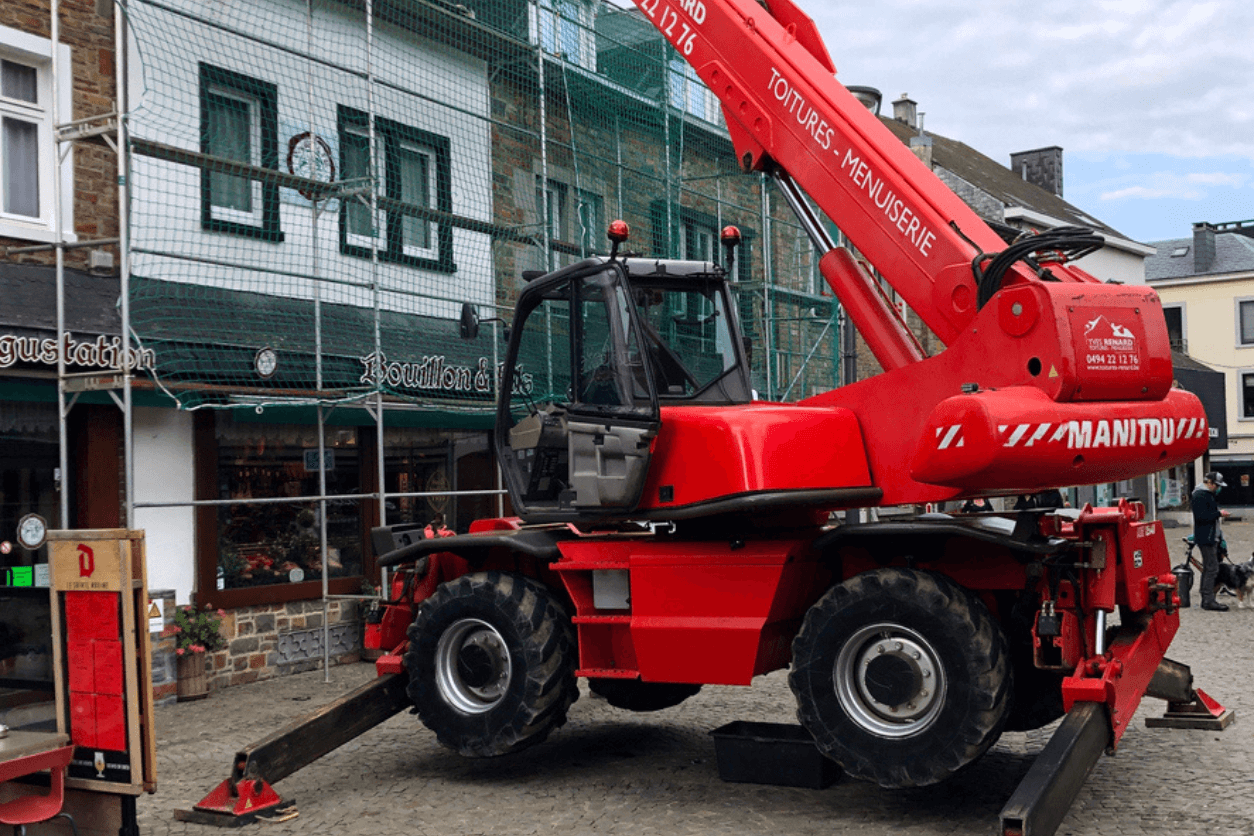

Your best defence against an unexpected breakdown is a rigorous daily pre-operational check for every Manitou telehandler . A minor fluid leak, a loose bolt, or a worn-out tire can easily go unnoticed. When operators ignore these small issues, they can quickly escalate into a catastrophic failure that halts the entire project, leading to expensive repairs and significant downtime.

A comprehensive checklist for a manitou telescopic forklift’s daily inspection is essential. This process gives you peace of mind, providing a documented record of the machine’s condition. While these checks are vital, they do not replace professional, regular servicing to keep your fleet in peak condition.

The Dangers of Ignoring the Load Chart

It’s tempting for an operator to trust their judgment to lift any load that “looks” like it will fit on the forks. They might even attempt one more “quick” lift, even if it’s slightly over the stated capacity, to save a trip.

The reality is that a manitou telescopic forklift is a precision machine with a complex load chart, a dynamic guide that changes based on the height of the boom, its extension, and the angle of the machine.

Ignoring this chart is the fastest way to cause a fatal tip-over accident. Overloading a telehandler will damage its chassis and strain hydraulic systems, creating an unstable, dangerous situation for everyone on the site. If you’re not sure, get out of the cab and check the chart. That one minute can save a disaster.

Train your operators to understand precisely how the manitou telescopic forklift’s capacity shifts with the boom’s position, and make sure they never exceed the stated limits.

Attachments: The Right Tool for the Job

Many operators mistakenly believe they can use the standard forks for every task or use attachments in ways the manufacturer did not design them for such as using a pallet fork as a makeshift lifting point for scaffolding.

Let’s be clear about this: each attachment is a specialised tool built for a specific job. Using an attachment incorrectly, or for a task the manufacturer did not design it for, is a major safety violation. It compromises the lift’s integrity and places unnecessary strain on the equipment, potentially leading to premature wear.

Employers need to provide specific training on each attachment their operators will be using. Using the right attachments on your Manitou telehandler prevents dangerous improvisation and makes the job safer and more efficient.

Blind Spots and the Absolute Need for a Spotter

Even an experienced manitou telescopic forklift operator might believe they have full control and can navigate a busy site alone, especially when a large load obstructs their view.

A busy construction site is a minefield of moving people and equipment, and the operator of a manitou telescopic forklift always has blind spots. A lack of clear communication and a reliable spotter creates a dangerous situation for moving personnel and other equipment, leading to costly collisions. These accidents can damage the machine and materials, and in the worst cases, can cause serious injury.

This is why you must make a trained spotter with clear hand signals a mandatory part of any lift where something obstructs the operator’s view. Establish and enforce clear communication protocols on site, including designated work zones and safety briefings, to ensure everyone is aware of the telehandler’s movements.

The Illusion of Speed: Why Slower is Faster

In a rush to complete a job, operators often believe that moving a manitou telescopic forklift faster will increase productivity. They may drive with excessive speed or make abrupt, jerky movements with the boom and hydraulics. That’s simply not true.

The reality is that a manitou telescopic forklift is an incredibly powerful but sensitive piece of machinery. The fastest way to cause a catastrophic accident is by making sudden movements, especially with a load at height or on a rough surface.

These aggressive actions create a dynamic load that is far greater than the static weight of the material being lifted. This can cause the machine to become unstable, leading to a tip-over. Jerky movements also place immense strain on the hydraulic and structural components, leading to premature wear and failure. The most efficient and safest way to operate a Manitou telehandler is with smooth, controlled movements. Taking your time and feathering the controls to ensure the machine is stable before moving is a critical safety measure.

Shifting from Mistakes to a Culture of Excellence

These common misconceptions aren’t just minor operator errors; they are dangerous assumptions that can have devastating consequences. By shifting your mindset from simply “avoiding mistakes” to building a proactive culture of safety, you can save valuable project time and money.

Our comprehensive expert telehandler servicing equips your team not just with the right machines, but with the knowledge and skills to operate them correctly. We also provide thorough inspections and documentation, ensuring your equipment always complies with regulations like LOLER and PUWER.

Don’t wait for the next error. Talk to a Glosrose expert today and make sure your team has the knowledge and support they need to operate safely, every time.

You May Also Like

How Doosan Fork Lifts Solve the Dock-to-Stock Bottleneck for High-Velocity Warehouses

Why Agility Overtakes Reach in Modern Urban Telehandler Selection

Get in Touch

Not sure what you are looking for or need some advice for your requirements? Get in touch with us today and a member of our experienced team will be more than happy to help answer your questions.